Description

Product Params

| Type | Sleeve | Specifications | Customized |

|---|---|---|---|

| Material | PA, ABS, POM, PP, PTFE, PE, PVC, TPU, etc | Customized | Customized |

| Certification | ISO, CE | Warranty | 12 Months |

| Usage | Power Station, Gas, Sewage Treatment, Public Works, Chemical, Papermaking, Pharmaceutical | Sample | Available |

| Color | Customized | Years in Industry | 40+ |

| Engineers | 50+ | Certificate | RoHS, CE, ISO9001 |

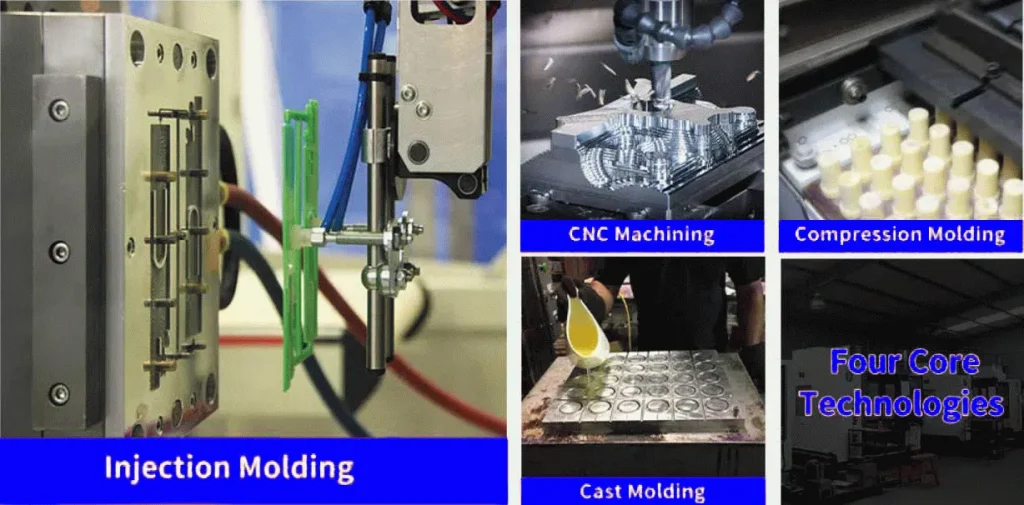

| Our Service | OEM / ODM | Technology | Injection, CNC, Compression, Casting, Extrusion |

| Customized Item | Molds & Products (Color, Material, Size, Surface) | Standards | Chinese Standard, ANSI, DIN, JIS |

| Material for Choose | Plastic, Rubber, Silicone, PU, Nylon, PVC, ABS, etc | Custom Color | Black, White, Red, Green, Transparent or Any |

| Biggest Part Size | 2000 × 2000 × 2000 mm | Tolerance | 0.01 mm – 0.001 mm |

| Free Samples | 1–5 pcs | Drawing Format | STEP / STP / IGS / STL / CAD / PDF / DWG |

| Package | Can Be Customized | Lead Time | 10–15 Days After Sample Confirmed |

| Transport Package | Customized Packaging | Specification | Customized Product |

| Origin | China | HS Code | 3923500000 |

| Production Capacity | 500,000 pcs / Month |

Wear-Resistant PTFE Slide Plastic Bushing

This product is a high-performance engineering plastic bushing made from PTFE (Polytetrafluoroethylene) material. Designed for applications involving continuous friction or frequent sliding, it offers an exceptionally low coefficient of friction and outstanding self-lubricating properties. Even under dry or low-lubrication conditions, it effectively reduces wear and energy loss.

The plastic bushing features excellent wear resistance, corrosion resistance, and high-temperature stability, making it suitable for various industrial environments such as mechanical transmission systems, automation equipment, chemical machinery, and precision instruments. Compared with traditional metal sleeves, PTFE bushings are lighter, more resistant to chemical corrosion, and eliminate issues like lubrication contamination and operation noise caused by metal friction.

With a compact structure and easy installation, this plastic bushins type is ideal for cleanroom or corrosive applications. Its durability and stable performance make it a reliable and cost-effective choice for designers seeking balance between longevity and efficiency in industrial equipment.

Application of Wear-Resistant PTFE Slide Plastic Bushing

As a reliable type of engineering plastic bushings, PTFE slide bushings are widely used in various mechanical transmission and support systems. In industrial machinery, automated production lines, and linear motion guides, they help reduce friction and ensure smooth, stable operation. Their naturally low friction coefficient and self-lubricating properties make them ideal for dusty or poorly lubricated environments, maintaining excellent wear resistance and dimensional stability even under long-term, high-frequency movement.

In the chemical and petrochemical industries, this plastic bushing demonstrates outstanding resistance to corrosive media. Whether used in chemical pipeline supports, mixer bearings, or valve assemblies, PTFE material withstands acids, alkalis, solvents, and oils without degradation. It provides long-term reliability and minimizes maintenance needs, making it well-suited for environments requiring chemical resistance or continuous operation.

PTFE bushings also perform exceptionally well in high-temperature or temperature-fluctuating equipment such as heating furnaces, dryers, power generation systems, and thermal treatment machinery. With excellent thermal stability, they maintain their mechanical properties without deformation or loss of performance. The stable thermal expansion behavior ensures precise alignment and consistent fit between shafts and sleeves, even under heat stress.

In addition, this type of plastic bushins is frequently used in food processing, pharmaceutical, and sanitary equipment. PTFE’s non-toxic, odorless, and easy-to-clean characteristics make it ideal for applications with strict hygiene and safety requirements. It eliminates the need for additional lubricants, helping maintain clean production environments while providing a durable and maintenance-friendly solution.

PTFE Bushing vs Copper / Bronze Bushing

Corrosion Resistance:

PTFE bushings perform exceptionally well in environments exposed to acids, alkalis, salt spray, and various solvents. They are highly resistant to chemical corrosion and ideal for humid or harsh conditions. In contrast, copper and bronze bushings tend to oxidize or rust over time when exposed to moisture or chemical agents, which limits their service life and increases maintenance needs.

Lubrication Performance:

PTFE is a self-lubricating material with a naturally low friction coefficient. It can operate smoothly even under dry or poorly lubricated conditions, reducing energy loss and minimizing maintenance costs. Metal bushings, on the other hand, rely heavily on lubricants such as oil or grease. Insufficient lubrication may cause wear, noise, or even seizure during operation.

Environmental Adaptability:

PTFE bushings maintain stable performance in dusty, humid, or chemically corrosive environments, where traditional metal bushings may struggle. Copper and bronze bushings are more suitable for high-load or impact-heavy machinery but require additional protection in demanding conditions.

Overall, PTFE-based engineering plastic bushings offer a lightweight, self-lubricating, and corrosion-resistant solution, making them better suited for mechanical systems that require long service life and minimal maintenance.

Customer Reviews

⭐⭐⭐⭐⭐

Michael Turner, Mechanical Engineer, Delta Automation, USA

We’ve been using the Wear-Resistant PTFE Slide Plastic Bushing in several of our robotic arms and conveyor systems. The self-lubricating feature really helps reduce maintenance downtime, and the performance has been consistent even under heavy workloads. Smooth motion, no noise, and excellent durability — exactly what we needed for continuous operation.

⭐⭐⭐⭐⭐

Sofia Müller, Production Supervisor, TechMotion GmbH, Germany

We replaced our old metal bushings with these PTFE ones, and the difference is clear. The plastic bushing runs quietly and doesn’t require frequent lubrication. It’s also highly resistant to chemicals, which is crucial in our production environment. A solid and efficient upgrade for our machinery.

⭐⭐⭐⭐⭐

Kenji Nakamura, Maintenance Manager, Osaka Precision Works, Japan

The Wear-Resistant PTFE Slide Plastic Bushing has performed perfectly in our high-temperature molding equipment. Even with continuous use, there’s no visible wear or deformation. The tolerance accuracy is excellent, and installation was very easy. Great balance of quality and cost.

⭐⭐⭐⭐⭐

Isabella Rossi, Plant Engineer, NovaChem Industries, Italy

We’ve been using these PTFE bushings in chemical mixers and valve systems for months now. They withstand solvents and acids extremely well and still move smoothly without lubrication. Maintenance has become much simpler, and equipment stability has improved. Highly reliable and worth recommending.

FAQ

What industries commonly use wear-resistant PTFE slide plastic bushings?

They are widely used in machinery, automation systems, chemical equipment, power generation, and precision instruments due to their excellent wear and corrosion resistance.

Can PTFE bushings operate without lubrication?

Yes. PTFE is a self-lubricating material that performs smoothly even under dry or low-lubrication conditions, reducing maintenance frequency and cost.

Are customized sizes and designs available?

Absolutely. We provide OEM/ODM services and can customize dimensions, materials, and colors according to your drawings or specific application requirements.

What is the typical lead time for production and delivery?

Standard lead time is about 10–15 days after sample confirmation, depending on order quantity and customization complexity.